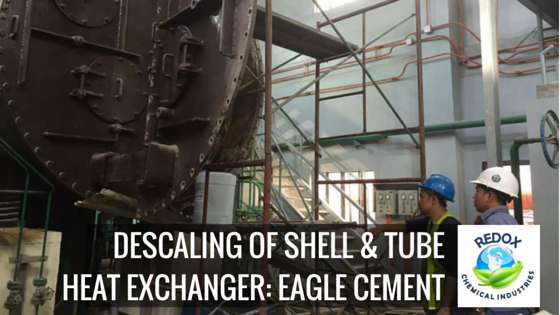

A leading corporation, that is Eagle Cement Corporation, approached Redox Chemical Industries Philippines last January 2016 with a very crucial project for cleaning and descaling of shell and tube heat exchanger of their waste heat recovery area. The enemy of heat exchanges efficiency is scale and sediment buildup. If the heat exchanger has a blockage or not properly clean there is the tendency that the pipe will explode. Working closely with the client, we co-engineered a process that met all of their requirements of heat exchanger descaling.

SCOPE OF WORKS (HEAT EXCHANGER):

I. SUPPLY OF LABOR, TECHNICAL SUPERVISION AND MATERIALS

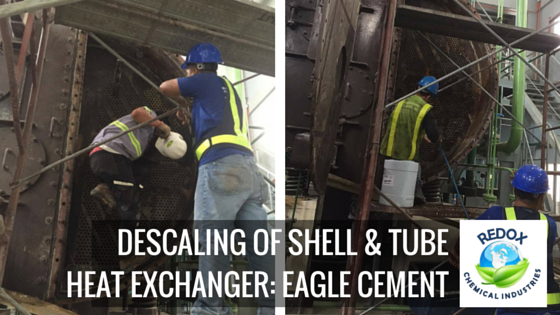

1. Mobilization.

2. Installation of temporary facilities at site area.

3. Shut off the unit isolation valves.

4. Injection and Circulation of descaling chemical into the unit for about 3 hours depending on the scale.

5. Flushing the tube.

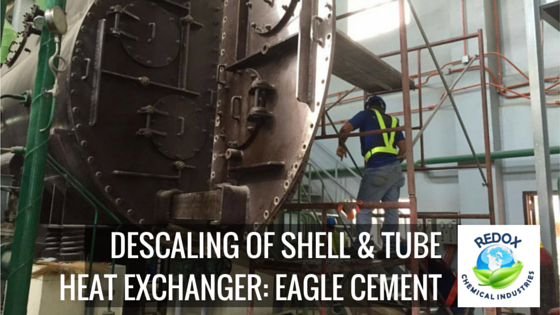

6. Chemical neutralization and initial rinsing.

7. High-pressure washer rinsing until the required pH is achieved.

8. Reactivation of unit isolation valves.

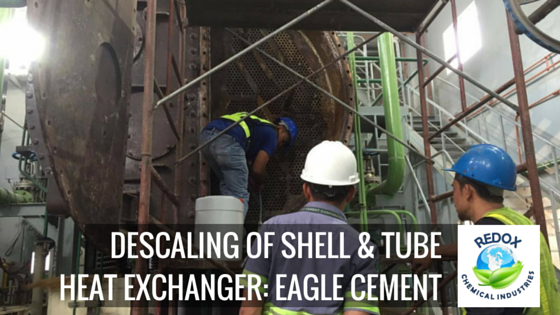

9. Testing and turn over.

10. Re-installation of the dismantled parts.